Leading wind measurement experts gathered in London claimed that LiDARs have been replacing met masts to become the sole wind measurement tool used for offshore resource assessment and power curve verification purposes.

These experts stated that LiDAR technology had over the years fully proven its ability to provide wind measurements as reliably as met masts. They also claimed that LiDARs are faster, easier and much cheaper to deploy, enabling significant development and operational cost reductions.

At a seminar hosted by Leosphere at the Offshore Wind Conference 2017, top wind measurement experts explained that years of successful LiDAR validation campaigns and strong competitiveness have led industry leaders to choose this technology over met masts for offshore wind feasibility studies as well as power curve verification tests.

“Experience has taught us that the uncertainty levels offered by LiDARs are at least on par with those offered by met masts. Although we still encounter performance misconceptions surrounding LiDAR technology, it is now hopefully a mere question of time before the industry as a whole recognizes this technology, and IEC standards are adapted accordingly,” explained Anders Thoft Marcussen, Head of Measurements at DONG

“Experience has taught us that the uncertainty levels offered by LiDARs are at least on par with those offered by met masts. Although we still encounter performance misconceptions surrounding LiDAR technology, it is now hopefully a mere question of time before the industry as a whole recognizes this technology, and IEC standards are adapted accordingly,” explained Anders Thoft Marcussen, Head of Measurements at DONG

Energy and chairman of the London LiDAR Seminar. In practice, the use of nacelle mounted LiDARs is already frequently required in the turbine supply agreement for power curve verification testing, even if LiDAR measurements are not yet covered by IEC standards.

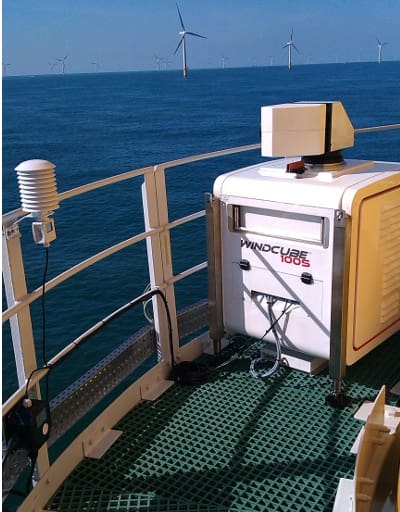

Met masts cannot compete with LiDARs on cost in the offshore market. On the Beatrice Offshore Wind Farm Ltd (BOWL) project, a 588MW 84 turbine offshore wind farm off the North East coast of Scotland, the wind measurement campaign was carried out without the use of a met mast. BOWL chose instead to install two vertical profiler LiDARs which enabled them to start the measurement campaign much earlier and without the significant costs associated with installing an offshore met mast. After 12 months of LiDAR wind measurement the project had the essential data needed to help achieve financial close on this £2.6 billion offshore project.

For an offshore project developed by RES, the installation of a met mast, estimated at €12 million, was ruled out in favour of a single fixed LiDAR, coupled with two floating LiDARs. The fixed LiDAR, installed on a nearby lighthouse, and the floating LiDARs located at points across the wind farm zone, enabled the company to secure reliable, bankable data adding millions of euros to the project value in addition to the millions in cost savings and the elimination of the health and safety risks associated with large met mast installation.

“LiDARs have become a reliable, robust measurement system that ultimately delivers the high-quality data to minimise uncertainty and risk while maximising value. The prevailing view among experts is that the future of resource assessment is short masts coupled with LiDAR for onshore, and for offshore probably just the LiDAR. Today, LiDARs are commercially ready and already used in major projects around the world. It’s a trend that is going to continue both offshore and onshore, even in complex flow sites,” concluded Alexandre Sauvage, CEO of Leosphere.

About LEOSPHERE

LEOSPHERE, founded in 2004, and its subsidiary AVENT Lidar Technology are world leaders in ground-based and nacelle-mounted LIDAR (Light Detection and Ranging) for atmospheric observation. The companies design, develop, manufacture, sell and service new turnkey remote-sensing instruments allowing wind measurement and aerosol characterization. LEOSPHERE has deployed hundreds of LIDARs throughout the world in severe environments. www.leosphere.com

About the LiDAR User Experience session: “Sharing LiDAR practices from financing to performance verification”

At the Offshore Wind conference 2017 in London, Leosphere brought its community together, offering a unique opportunity for users to challenge their views and learn about the potential offered by LiDAR technology, quickly becoming a standard in offshore. Major offshore wind energy players have shared their experience on a wide range of applications, from energy yield assessment to contractual power performance testing. Best practices in offshore Lidar applications from different perspectives were presented, with case studies from developers, OEMs and consultants.

- Deutsche WindGuard, Klause Franke, Project Engineer: “Application of Nacelle Based Lidar for Offshore Power Curve Tests”

- ECN, Hans Verhoef, Project Leader Measurements: “Offshore wind development with standalone Lidar”

- EDF EN, Cedric Dall’Ozo, Senior Wind Resource Assessment Engineer: “Reducing uncertainties: vertical profiler, floating, scanning and nacelle Lidars”

- MHI Vestas, Tue Hald, Senior Specialist: “Power curve verification with nacelle two-beam Lidar on V164-8.0 MW”

- RES, Iain Campbell, Technical Analyst and Wind Resource Manager: “Lidar: Just better than a mast?”

- Siemens, Pedro Salvador, rotor Performance engineer: “From R&D to Plug & Play: 8 years of nacelle Lidar experience”

- SSE, Gordon Day, Offshore Wind Analyst: “Replacing masts with Lidar for financing and performance assessment”

- UL DEWI, Beatriz Canadillas, Senior Researcher: “Offshore Wind Lidar since 2009: from R&D to commercial applications”