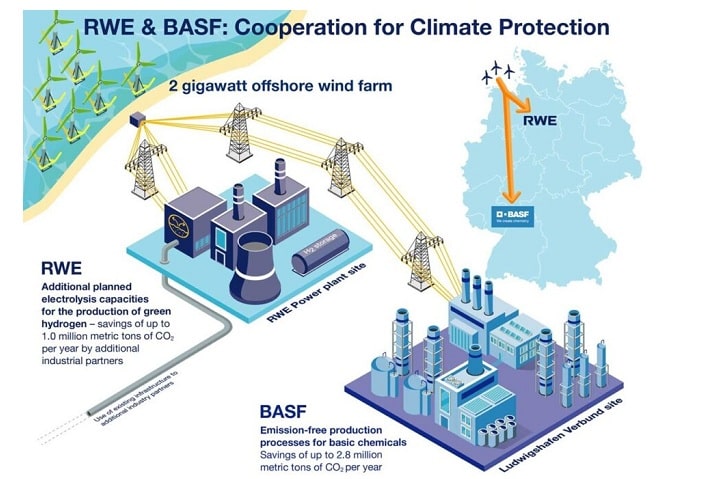

In Ludwigshafen, Germany, Dr. Martin Brudermüller (BASF) and Dr. Markus Krebber (RWE), accompanied by Chairman of the Mining, Chemical and Energy Industries Union (IG BCE) Michael Vassiliadis, presented a project idea that envisions a new 2 GW offshore wind farm in the German North Sea to provide the Ludwigshafen chemical site with green electricity and enable CO2-free production of hydrogen.

The aim of the “Offshore-to-X” project is to electrify the production processes for basic chemicals, which are currently based on fossil fuels.

The 2GW wind farm will produce around 7,500 GWh of green electricity per year This would be in addition to the planned 20 GW by 2030 in existing legislation. The green electricity would therefore meet the criterion of additionality.

The potential offshore sites for this project are ones that are currently only planned for the period after 2030 according to Germany’s Site Development Plan and Network Development Plan. RWE will develop, build and operate the wind park. BASF will own a stake.

Around 80% of the approximately 7,500 GWh produced by the wind park will be supplied as green electricity for innovative technologies for CO2 reduction and thus power the transformation of BASF sites in Germany, especially the Verbund site in Ludwigshafen. Examples of such technologies are:

eCracker: Electrically heated steam cracker furnaces to produce petrochemicals at high temperatures (~850 °C); these temperatures will be reached in the eCracker using electricity instead of natural gas.

Methane pyrolysis: Methane pyrolysis uses green electricity to split methane into hydrogen and carbon. The hydrogen can be used, for example, to produce green ammonia. Another output of this process is high-purity solid carbon, a valuable raw material that can replace carbon in various industrial sectors, such as the steel industry.

Power-to-heat: Electrode boilers and high-temperature heat pumps will make it possible to use green electricity instead of fossil fuels to produce process heat.

Around 20% of the electricity produced by the wind park would be used to produce green hydrogen in northwestern Germany—approximately 30 million kilograms of green hydrogen per year for use in other industrial segments.

To advance the joint project, the CEOs of BASF and RWE have signed a letter of intent covering a wide-ranging cooperation for the creation of additional capacities for renewable electricity and the use of innovative technologies for climate protection.

These plans could result in the avoidance of around 3.8 million metric tons of CO2 emissions per year, of which 2.8 million tons would be realized directly at BASF in Ludwigshafen. It shows very clearly how climate protection and competitiveness can be harmonized in the chemical industry. No public subsidies would be needed for the construction of the wind farm.

Realizing this plan will require a suitable regulatory framework. Policymakers have said they plan to increase the expansion targets for renewable energies significantly and to accelerate capacity additions. For this to succeed, there will need to be a tendering process for offshore project sites where the current plans only foresee use after 2030.

The companies say that these sites should be specifically designated for tenders focused on industrial transformation processes. Another important factor: Green electricity should not be subject to EEG levy. In addition, there is currently no regulatory framework for CO2-free hydrogen production.