The Core responsibility of the O&M team is to Operate and Maintain the plant to deliver guaranteed plant performance during the O&M period and delight the Customer. The Owners’ expectations are dependent on maximized generation and longevity of plant life as being the critical levels.

This is delivered through robust design, quality execution and efficient O&M as the main levers. Plant Operations would mainly include activities such as module cleaning, plant security, optimal spares management, vegetation clearing and overall plant up-keep. Plant Preventive Maintenance includes regular maintenance activities done as per pre-decided schedule, while Break-down Maintenance includes trouble-shooting activities done to restore plant performance levels post a failure. This along with regular reporting of the plant performance metrics, failure analysis and value engineering initiatives ensures optimal plant performance.

This is delivered through robust design, quality execution and efficient O&M as the main levers. Plant Operations would mainly include activities such as module cleaning, plant security, optimal spares management, vegetation clearing and overall plant up-keep. Plant Preventive Maintenance includes regular maintenance activities done as per pre-decided schedule, while Break-down Maintenance includes trouble-shooting activities done to restore plant performance levels post a failure. This along with regular reporting of the plant performance metrics, failure analysis and value engineering initiatives ensures optimal plant performance.

Global O&M Market

As per the GTM Research analysis, the total addressable market for megawatt-scale PV plant asset management and O&M services is expected to reach 182 GW by the end of 2016. As the global market continues to develop, the relative weight of European markets is expected to shrink as large volumes of new capacity additions happen in other countries: by 2021, China alone is expected to represent 35% of the global installed capacity, followed by the U.S.with 20% and India with 13%.

O&M in India- Key Trends

A typical Solar PV plant has life of over 20 years, with lowering tariffs in India, the O&M of the plant has become all the more critical to ensure overall profitability of the plant and can impact the project IRRs significantly.The market has matured significantly over the last few years. While the plant sizes are increasing, the developers are also expecting better performance levels. There’s an increased requirement of higher performance guarantee and plant availability numbers. This coupled with reducing price expectations, is making the market highly competitive to operate in. Survival in the market can only be ensured through best in class service offerings, aligned with customer expectations, at competitive pricing.

With the emergence of secondary market for old solar assets, asset management requirements have also been emerging in the market. Asset management duties do not necessarily involve any on-site presence, but rather involve the coordination and supervision of O&M activities at site. Also, timely reporting and accuracy of plant performance metrics is a critical requirement of the developers, which is increasingly being met by SCADA interfaces, rather than relying on manual recording.

Challenges faced

While the O&M story is on a growth path it doesn’t come free of challenges. Grid issues is one of the major challenges affecting O&M in India, resulting from grid throttling, grid variations and instability, which eventually results in equipment under performance and increased downtime.

With reducing prices, there’s an increasing pressure to optimise processes to in-turn optimise costs. Security is the biggest contributor to the cost, followed by site manpower and module cleaning cost. Therefore, increased dependence on technological alternatives for plant surveillance, module cleaning and remote monitoring for plant performance will be critical to optimise critical cost components and stay competitive in the market.

Since most of these plants are located in remote locations, a lot many times local issues also start emerging like theft, vandalism, protests, arm twisting for rates etc., which need to be mitigated to ensure smooth functioning of the plant. This requires dedicated efforts to take up sustainability and CSR initiatives, provide them skill training and create jobs to ensure local inclusion.

Mahindra Susten’s O&M services

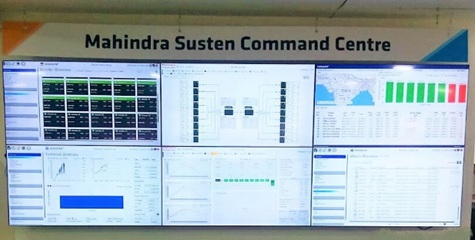

Susten’s O&M portfolio which started off at 29MWp in 2013, has reached up to 450MWp currently, with another 500MWp in the pipeline.The current portfolio is spread over 60 sites including 30 Utility scale solar PV plants and 30 rooftop sites across top 10 solar states in India. With a dedicated team of 100+ members, the portfolio has been compartmentalised into 3 regions, namely Region 1 comprising of Rajasthan, UP and MP, Region 2 comprising of Telangana, AP and Karnataka and Region 3 comprising of Tamil Nadu, for optimal man-power utilisation and control.Central Command Centre, based out of Mumbai, does remote monitoring, remote troubleshooting and control across sites. In-house domain expertise results in continuous performance monitoring and advanced analytics to ensure plant performance maximisation, equipment under-performance detection, trend analysis and forecasting and predictive analytics for reduced plant down-time.  With an experience of 5 years in the O&M business, Susten has consistently surpassed the performance guarantees committed to its clients, with the portfolio level uptime being above 99.5% and Performance Ratio (PR) being above 102% of the guaranteed PR. All this with no compromise on the site security, with 1.7 million safe man-work hours, certified by OHSAS 18001:2007 in Occupational Health & Safety. Also, our Integrated Management System (ISO 9001:2015, ISO 14001:2004) acts as guiding principle to take up initiatives for local inclusion. To communicate our efforts, GRI G4 reporting guidelines are being followed and reported over 30 indicators.

With an experience of 5 years in the O&M business, Susten has consistently surpassed the performance guarantees committed to its clients, with the portfolio level uptime being above 99.5% and Performance Ratio (PR) being above 102% of the guaranteed PR. All this with no compromise on the site security, with 1.7 million safe man-work hours, certified by OHSAS 18001:2007 in Occupational Health & Safety. Also, our Integrated Management System (ISO 9001:2015, ISO 14001:2004) acts as guiding principle to take up initiatives for local inclusion. To communicate our efforts, GRI G4 reporting guidelines are being followed and reported over 30 indicators.

Sensing the market requirements, Susten has also diversified into plant testing and audit services. We have an in-house specialised team, equipped to do field testing across solar PV plant equipment. The skilled team does detailed technical assessment of the plant and suggests the potential and suggestions for plant performance improvement to ensure optimal returns for the developer and prolonged plant life.

Ms. Ruhi Gupta is part of the coveted GMC program of Mahindra & Mahindra and is currently serving as Manager-BD for the O&M and Analytics department of Mahindra Susten. In her current role, she’s responsible for ensuring O&M business process optimization and expansion.

Prior to this role, Ms. Ruhi was working with GE in the Energy Consulting division where she worked on power market dispatch modelling and conducted global energy market research on demand-supply trends, generation expansion and energy policies.

Ms. Ruhi is an MBA in International Business from IIFT, Delhi and BE in Electrical Engineering from PEC University of Technology, Chandigarh.

Name: Ruhi Gupta

Designation: Manager – BD, O&M

Email: GUPTA.RUHI@mahindra.com

Contact Number: +91 22 61741618

About Mahindra Susten

Mahindra Susten is the clean-tech arm of the Mahindra Group and one of the fastest growing portfolio companies under the $1 billion Mahindra Partners. In 5 years we have established ourselves as one of the leading companies within the Indian solar industry and have been declared the Top EPC company for the 2nd consecutive year by Bridge to India.

Our team of more than 750 personnel challenges conventional thinking at every step to deliver smart and sustainable solutions. That is our process. That is our commitment. Powered by innovation, driven by quality and fuelled by excellence, we are uniquely positioned to enable every Indian business, household and individual to RISE with clean and smart solutions.