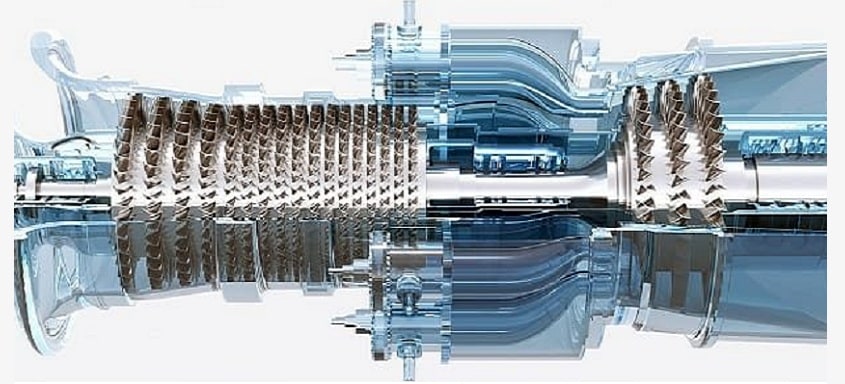

GE Power (www.GEPower.com) announced the new MXL2 with Additive Manufactured Performance (AMP) the world’s first upgrade solution for GE’s GT13E2 gas turbines that uses key components manufactured using additive technology.

The addition of additive manufactured parts into the MXL2 solution represents a turning point in the global power generation industry and confirms GE’s commitment to keep its mature fleets competitive in today’s very dynamic marketplace. The new technology can help gas plant power producers save up to $2 million in fuel annually, while opening up the potential for additional revenue of up to $3 million annually in new power capacity. Today’s news also marks the third investment announcement GE Power is making in six weeks in its Power Services business.

“We’re continuing to invest in new technologies to keep our installed base competitive: the new MXL2 with AMP upgrade could not be manufactured with conventional methods and marks the first-of-its kind solution with the injection of components manufactured by additive technologies,” said Scott Strazik, president and CEO of GE’s Power Services business. “Because these components are made with a lightweight configuration and can be engineered to include advanced cooling channels, they help the gas turbine run more efficiently, representing a new frontier in turbine engineering and production. These savings translate directly into increased performance and provide turbine operators with greater fuel efficiency and more capacity. We’re excited to bring this technology to our GT13E2 fleet, which we acquired from Alstom in 2015.”

The new MXL2 with AMP include two components produced by GE’s Additive Manufacturing Works (AMW) teams in Birr, Switzerland, and Greenville, South Carolina, United States: the first-stage turbine vanes and heat shields. These parts are among the turbine’s hottest-running components, and the significant amount of cooling air they traditionally require impacts the engine’s performance. Additive printing allows GE to use advanced cooling designs that considerably reduce the amount of cooling air the parts need, improving the turbine’s performance and offering operators potentially millions of dollars in benefits per year.

The breakthrough technology can significantly elevate the output and efficiency of existing GT13E2 gas turbines. It’s capable of:

- Reducing component cooling requirements by up to 25 percent.

- Increasing output up to 21 megawatts (MW) in combined-cycle configuration.

- Achieving efficiency improvement of up to 1.6 percent in combined-cycle configuration.

- Delivering maintenance intervals of up to 48,000 hours.

Latest Game Changer in Additive Technology at Vattenfall’s Heizkraftwerk Berlin-Mitte Power Plant

The MXL2 with AMP upgrade is a direct result of GE’s long-term commitment to additive manufacturing technology. Vattenfall began supporting this technology in 2015 with the installation of four different 3D printed components at its Heizkraftwerk Berlin-Mitte Power Plant near Germany’s capital city of Berlin.

GE’s Hardware Upgrades Help Increase Efficiency and Output at Azito Power Plant in Ivory Coast and SPDC in Nigeria

GE (www.GE.com/power) implements and supports power projects across Africa with the aim of strengthening the power sector by providing innovative power solutions. Some of the recent MXL2 upgrade projects includes Azito Energie S.A. (http://www.azitoenergie.com/fr/) (Azito) who signed an agreement to upgrade two gas turbines at the company’s combined-cycle power plant and marks GE’s first GT13E2 MXL2 gas turbine upgrade (https://goo.gl/gTZbdY) order in Sub-Saharan Africa.

Also, MXL2 upgrade on Shell Petroleum Development Company’s (SPDC) Afam IV plant (https://goo.gl/L45SgV) will add additional 30MW capacity, enough power for approximately 200,000 Nigerian homes. In addition to increasing power output by up to 30 MW, upgrades on the turbines are expected to deliver a combined-cycle efficiency increase, resulting in significant fuel savings and reduced CO2 emissions. GE’s solutions will also extend inspection intervals for the gas turbines, reducing maintenance and repair expenses—which, in turn, will reduce overall plant costs and result in improving profitability.

GE (www.GE.com) is the world’s Digital Industrial Company, transforming industry with software-defined machines and solutions that are connected, responsive and predictive. GE is organized around a global exchange of knowledge, the “GE Store,” through which each business shares and accesses the same technology, markets, structure and intellect. Each invention further fuels innovation and application across our industrial sectors. With people, services, technology and scale, GE delivers better outcomes for customers by speaking the language of industry. www.GE.com

About GE Power

GE Power (www.GEPower.com) is a world leader in power generation with deep domain expertise to help customers deliver electricity from a wide spectrum of fuel sources. We are transforming the electricity industry with the digital power plant, the world’s largest and most efficient gas turbine, full balance of plant, upgrade and service solutions as well as our data-leveraging software. Our innovative technologies and digital offerings help make power more affordable, reliable, accessible and sustainable. For more information, visit the company’s website at www.GEPower.com

About GE’s Power Services

GE’s Power Services, headquartered in Baden, Switzerland, delivers world-class service solutions for our customers across total plant assets and their operational lifetimes. This organization supports 2,800+ customers worldwide with an installed base of 28,000+ power generation assets across 90+ brands of power generation equipment and taps into the Industrial Internet to improve the performance of our solutions over the entire life cycle through the power of software and big data analytics.