The Global Energy market is undergoing a period of rapid and continuous transformation.

Energy demand has doubled in the last forty years and this trend will not stop in the coming years driven by the needs of human and economic development and above all by the progresses in industrialization and education bringing wealth in countries such as China and India.

Connected to the rising energy demand countries are facing the issue of climate change and are becoming more and more aware of the need to implement new stringent policies and regulatory requirements to reduce green house gas emissions for a sustainable future. The way to meet new climate targets whilst satisfying the energy demand requires cleaner power generation technologies and a more efficient use of the energy resources available.

In this transforming scenario where renewables get most of the press, the often forgotten waste heat recovery technologies which offer energy savings and ensure effective re-utilization of exhaust heat wasted in power generation processes are quietly growing in popularity.In fact increased energy efficiency via heat recovery is one of the key solutions to cope with the challenges of the energy market.

In this transforming scenario where renewables get most of the press, the often forgotten waste heat recovery technologies which offer energy savings and ensure effective re-utilization of exhaust heat wasted in power generation processes are quietly growing in popularity.In fact increased energy efficiency via heat recovery is one of the key solutions to cope with the challenges of the energy market.

Developing and emerging countries of the APAC region looking for energy efficiency to boost sustainable growth will play an important role in the installations of waste heat recovery systems. The potential for growth of the waste heat recovery systems in the APAC market is high now and is likely to continue to grow in the near future.

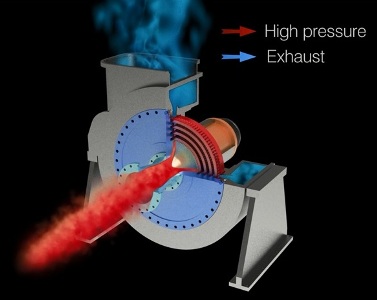

Organic Rankine Cycle is a common waste heat recovery technology utilized to produce clean electricity from waste heat generated by, amongst other things, reciprocating engines and gas turbines used in distributed power systems widely employed in APAC emerging countries. This technology has proven to give higher efficiency for medium-low temperature applications as well as more flexibility and competitive capital costs. Recent economic improvements have come about with the latest R&D involving the ORC technology through the introduction of the innovative Radial Outflow Turbine (ROT) technology. This new turbine configuration, converting the energy of the organic fluid with higher efficiency than the axial or radial inflow turbine, traditionally employed in an ORC system, has given a major opportunity to minimize economic investment for a WHR system whilst increasing efficiency and profitability in electricity production and reduction in environmental footprint.

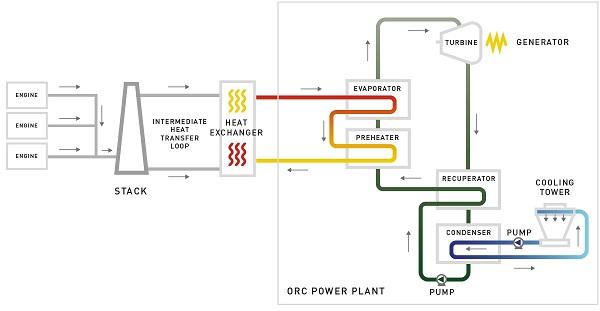

Organic Rankine Cycles are Rankine cycles operating with organic fluids selected on thermodynamic criteria and techno-economic optimization. An intermediate circuit extracts the heat from the thermal source to evaporate the working fluid in a heat exchanger. The organic fluid is expanded in a turbine to produce electric energy. At the turbine outlet, the fluid is liquefied releasing heat to a cold medium (air or water) and then is pumped at the maximum cycle pressure. Where there is a high temperature of the working fluid at the turbine outlet, the use of a recuperator to pre-heat the liquid can dramatically increases the efficiency of the overall system; this solution is usually implemented for higher temperature sources.

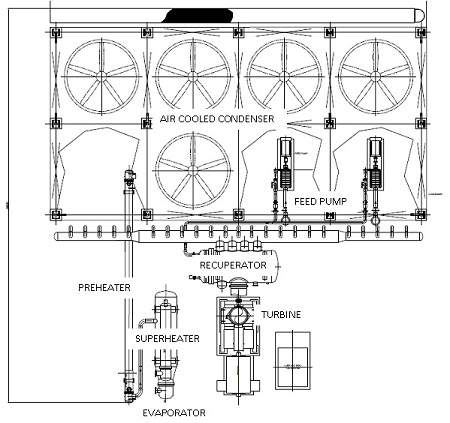

The main components of an ORC system are thus the turbine, the heat exchangers, the feed pump, the condenser. Considering the small number of components and its configuration as a stand-alone package, this system can be installed rapidly and easily, without substantial increase in operational costs or footprint.

The advantages of an ORC system over a steam Rankine Cycle for waste heat recovery application can be summarized as:

- Higher efficiency for small and medium size applications at a variety of operating temperatures.

- Fast start up and shut down of the plant

- Fully automated operation meaning minimum costs for Operation and Maintenance and for dedicated personnel

- No need of make-up water for the cycles operation.

- Flexibility of installation, even away from the heat source if required

- More competitive capital costs

Traditionally Organic Rankine Cycle systems have always employed axial or radial Inflow turbines. EXERGY introduced a new cutting-edge turbin e configuration, known as Radial Outflow Turbine (ROT), which has proved to increase the efficiency of ORC systems.

e configuration, known as Radial Outflow Turbine (ROT), which has proved to increase the efficiency of ORC systems.

Employing the Radial Outflow Turbine technology in an ORC system for WHR applications is simpler, more efficient and economically viable solution bringing several advantages:

- Higher efficiency than an axial turbine. This higher performance is related to :

- Up to 6 stages on a single disk reducing the size and length of the turbine compared to axial turbine

- Excellent expansion ratio as the fluid moves out across the disc

- Less tip leakage and disk friction losses

- Minimum 3D effect thanks to the low blade height and low blade height variation

- No gearbox needed thanks to the low rotational speed (3000-1500rpm) that allows a direct coupling with a generator with 2 or 4poles and higher reliability for the overall system

- Less limitation on cycle pressure and on blade manufacturing leading to a superior flexibility extending the range of application

- Lower vibrations which lead to a longer life of the plant

- Simpler construction technology, more compact and easy to transport and install

- Easy and low cost maintenance. The mechanical group of the turbine containing the bearings, oil lubrication system and seals can be easily removed without need of draining the organic fluid away from the cycle thus reducing the downtime of the plant to 6 hours during maintenance. This compares to the need for fluid drainage, and therefore approximately 1 week or more for other turbine technologies.

All the advantages offered by this ORC plant configuration using the ROT turbine translate into economic benefits and more competitive initial capital investments. Installing this ORC WHR system has a typical payback time of 3 to 7 years depending on the electrical output of the ORC required, and the market conditions

The application of EXERGY’s ORC waste heat recovery systems utilizing the ROT can be efficiently applied for waste heat recovery from engines and small gas turbines generating anywhere between 1 and 50 MW of extra power. The modular design of the ORC plant allows to install additional ORC units over time to exploit more waste heat and increase the power output and the overall energy efficiency of the installation.

Case study

EXERGY has studied different ORC WHR solutions for applications to engines and turbines. The case study we present here is for a Waste Heat Recovery system which recovers the exhaust gases from 16 natural gas Jenbacher engines. The project has been studied for a potential client located in Southeast Asia.

Characteristics of the plant and of the WHR system applied:

The ORC power plant is composed of two parts:

1) Waste heat recovery system needed to transfer the heat from the source to the ORC cycle, consisting of:

Waste heat recovery exchanger that transfers the heat from the exhaust gases to a thermal oil reaching an inlet temperature to the ORC system of 315°C.

- A thermal oil tunk

- A thermal oil pump

- A thermal oil emergency cooler

- A thermal oil loop interconnecting the Waste Heat recovery system to the ORC module

2) the ORC module where the main components are shown in figure n° 5include preheater, evaporator, a superheater to heat up the vapour of working fluid coming out from the evaporator before this entering the turbine. An air cooling system has been chosen as a condensing system thus eliminating any use of water and the cost and complexity of any water treatment system.

The chart below shows a business plan on a duration of 10 years for different electricity price scenarios with profitability and return on investment for this ORC WHR system.

Conclusion

EXERGY’s ORC WHR systems using the Radial Outflow Turbine are a practical and competitive solution to recover heat losses from reciprocating engines and small gas turbines employed in power stations and distributed power systems. This solution help producing clean electricity to meet extra energy demand with a sustainable process that increase the efficiency of the available resources and cut down carbon emissions. EXERGY has already installed 18 waste heat recovery ORC systems worldwide for different applications in industrial sector.

Anthony Hinde graduated from Nottingham University in the UK with a BEng (Hons) in Mechanical Engineering. Most recently he obtained his MBA from Purdue University in the US and Tilburg University in the Netherlands.Anthony has worked in the power industry for over 13 years, specializing in both heat recovery and Organic Rankine Cycle (ORC). He has spoken at a number of the leading industry forums, and is a Chartered Engineer.As International Marketing and Sales Director for EXERGY, Anthony services clients across the globe, with in-depth specialist knowledge. He also manages the sales team and oversees the strategic marketing direction of the business.

Anthony Hinde graduated from Nottingham University in the UK with a BEng (Hons) in Mechanical Engineering. Most recently he obtained his MBA from Purdue University in the US and Tilburg University in the Netherlands.Anthony has worked in the power industry for over 13 years, specializing in both heat recovery and Organic Rankine Cycle (ORC). He has spoken at a number of the leading industry forums, and is a Chartered Engineer.As International Marketing and Sales Director for EXERGY, Anthony services clients across the globe, with in-depth specialist knowledge. He also manages the sales team and oversees the strategic marketing direction of the business.

EXERGY design and manufacture Organic Rankine Cycle (ORC) systems with the innovative Radial Outflow Turbine (ROT) technology for power generation from renewable energy sources and waste heat recovery.

- EXERGY design, produce and supply innovative ORC engines for the following applications:

- Waste Heat Recovery from industrial processes and power stations

- Geothermal

- Biomass

- CSP (concentrated solar power)

Thanks to the use of the ROT technology, EXERGY’s ORC plants offer superior efficiency (up to 6% more than axial turbines), extreme flexibility for changing geothermal fluid conditions due to a higher number of stages, cost effective, multiple pressure level plants with single turbine disk. EXERGY’s solutions are available from small modular units to tailored plants with turbines up to 25 MW each.

- EXERGY undertake a complete in house production:

- Development of the ORC turbine and plant

- Engineering

- Manufacturing and Testing

- Project Management

- Long term After Sales Service

EXERGY has a current portfolio of over 350 MW of electrical power in operation or under delivery and a global annual turnover of approximately 100 million USD (2015 figure). EXERGY is part of the Maccaferri Industrial Group, an Italian corporation with an annual turnover of 1.3 billion USD, 58 production plants and 5,000 employees worldwide.