The world faces a unique conundrum. Electrification of lifestyles is expanding around the globe. The way people drive, cook, communicate, and more are continuing to consume greater amounts of electricity on a nearly daily basis. However, at the same time, citizens, governments, and even businesses are calling for new, greener ways to generate the power necessary to meet increasing demand. To respond to this call, power generators around the world are looking for new ways to increase their output of renewable energy, and India is no exception.

With India’s announcement that it aims to reach net zero emissions by 2070 and meet 50% of its electricity requirements from renewable energy sources by 2030, the government has set ambitious goals. Meeting those goals will mean harnessing every renewable resource possible in coming years, and one key element of that strategy is a solution that has been steadily gaining traction for many years—wind generation. Today, many of the wind turbines across the country are not up to that task. The existing turbines that independent service providers (ISP) are acquiring as they expand their operations are either outdated, inefficient, or both. Moreover, as producers acquire new equipment, they cannot guarantee those turbines will all be from the same original equipment manufacturer (OEM), which can make operations and maintenance far more complex (Figure 1).

These organizations could choose to completely replace existing turbines that do not meet their needs, but savvy owners and operators have discovered that there is another, more cost-effective way to get better performance out of their existing wind equipment: turbine control system retrofits coupled with fit-for-purpose green energy supervisory control and data acquisition (SCADA) software. Using such a strategy, power generators gain more access to data, more flexible and powerful control options, and better visibility across their entire operation while reaping a faster return on investment than is possible with turbine replacement.

Why choose retrofit over replacement?

Wind turbine technology has been in existence for a long time. As a result, many of the turbines operating across India are many years, if not decades old. Though turbines can and do often run past the decade mark, their performance begins to degrade quickly as they age. The internal components of a turbine are both electrical and mechanical, which means many of the parts wear down over time. Replacing these parts on legacy turbines can often be costly, and with each passing year, the parts become harder to source.

In addition, as turbines reach 10 or 15 years of operations, OEM support contracts often run out. In such a situation, teams face a difficult choice—spend more to maintain limited access to data through the OEM SCADA and service contracts, or let contracts expire and continue to operate in a severely limited fashion.

To meet this need for better wind technology, India’s Ministry of New and Renewable Energy has enacted the National Repowering Policy for Wind Products. This policy encourages wind generators to replace their turbines with higher-performance models to increase the potential output across the country. Moreover, new technology affords increased power and efficiency, as well as better control options. However, replacing a legacy wind turbine with a new model is not always the best choice. New installations are costly, complex, and time consuming. In addition, companies that replace their legacy turbines with new models, often find themselves locked into new limiting contracts with OEMs that restrict their access to critical data and will put them back in the same situation 10 years down the line.

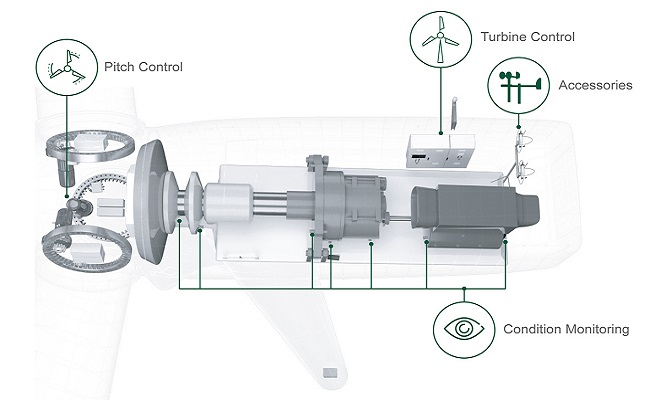

To circumvent this conundrum, many power generators are choosing wind turbine control retrofits over turbine replacements. In a retrofit, an experienced automation partner removes legacy control modules from existing turbines and replaces them with an entirely new control system. The new control system can be connected directly to legacy connections, reducing the amount of mechanical work necessary in the cabinet and enabling technicians to complete the project in a day or two (Figure 2).

Retrofits increase value with improved controls

One of the key benefits operations and maintenance teams gain from a turbine control retrofit is increased access to data and control logic. In most cases, OEM control systems significantly limit the amount of data users can access. Some of the most valuable operation parameters are trapped inside the control system, accessible only to OEM personnel. If teams can gain access to the data they need via the manufacturer—which is not always possible—doing so is typically a costly and time consuming process.

Consider the recent example of a large ISP in India that wanted to identify the reason for sudden frequency fluctuations in some of their turbines. The OEM SCADA system report did not include the parameters the operations and maintenance teams needed to effectively diagnose and solve the problem. They lacked access to critical turbine control parameters and power production levels at the specific time of the fluctuations. The OEM was able to provide the necessary data, but at a cost that was prohibitive to trending the data over the long period of time necessary to determine root cause.

The most advanced retrofit control systems provide users with 5 to 10 times the parameters of most OEM solutions. They are designed to unlock all the data available from the turbine to give the operations and maintenance teams full ownership. Armed with dramatically more data than they had previously, teams can better track and trend performance of their equipment and make the operational changes necessary to improve production.

Better data drives better performance

Modern controls can do more than simply solve problems. In most cases, modern control logic provides operations teams with control strategies that help them increase their performance. For example, teams can uprate power on their turbines for additional production. Or teams can use advanced load control techniques to manage poor performance created by misalignment. Legacy turbines are commonly 4 to 10 degrees out of alignment for optimal performance. A modern control system will give teams the operational data and configuration options they need to adjust yaw and pitch to reduce or eliminate that misalignment. Ultimately, teams taking advantage of the benefits of modern control typically see significant increases in annual production (Figure 3).

Better visibility drives better operations

The same automation partners that provide the most advanced turbine control system retrofits also offer purpose-built green energy automation solutions portfolios to help companies manage their operations across the enterprise. For example, green energy SCADA software can be used to bring every renewable energy asset—wind, solar, battery, hydroelectric, and more—into a single pane of glass for easier operation and maintenance. Combining all assets in one SCADA solution eliminates the need for operators to log into multiple OEM SCADA systems to track, trend, and control their assets. Operators can instead see everything they need from one consistent interface, reducing the need for travel and training, and reducing the time it takes to solve problems (Figure 4).

A more efficient way forward

While complete turbine replacements are a great option to drive increased performance, they are not always the best solution for every power generator. Fortunately, a turbine retrofit can bring many of the same benefits as replacement—increased performance, better visibility, optimized operations and maintenance—while delivering less downtime and faster return on investment. Coupled with additional built-for-purpose green energy automation solutions such as green energy SCADA systems, retrofits can transform a company’s renewable energy portfolio, driving enhanced performance and productivity across all their green energy operations.

About Author

Shubhi Goel,

Shubhi Goel,

Emerson,

Shubhi Goel, a seasoned industry professional with over 18 years of experience, has spent the last 8 years at Emerson in various roles, specializing in product marketing and business development for power and renewable power plant generation. Currently serving as the Asia Pacific renewable business development leader and global proposals and tendering leader, she also holds responsibility as the renewable segment leader for the S&D program in Asia Pacific. With a Bachelor of Technology in Instrumentation and Control Engineering with meritorious results from the Kurukshetra University of India, Shubhi brings a blend of technical expertise and strategic vision to her role. She is known for her passion, hard work, agility, and customer-centric approach, believing strongly in teamwork and proactive leadership. Shubhi currently resides in New Delhi, India.